A poultry house ventilation system is arguably the most important management tool for a farm manager to use. As the birds grow and climates change the system needs to be able to adapt and cope with the changing demands to keep the birds in their comfort zone which ensures optimal biological performance. During periods of cold weather or brooding when the house temperature is at or below the bird comfort temperature, it is essential that we provide the birds with good quality air while maintaining temperature set point.

The only way to determine if the ventilation system is set correctly is to look at bird behaviour. Always use climate control systems as a guide and never the sole gauge of a turkey house’s suitability for bird comfort. If bird behaviour indicates that changes to ventilation are required, those changes should be made swiftly to ensure birds are kept as comfortable as possible.

Minimum ventilation is used when the house temperature is at or below the required house set-point temperature or bird comfort temperature. It is most commonly used during brooding or during cold weather.

In a well-sealed, air tight house, when an extraction fan is switched on, air will start to leave the house through the fan and then pressure inside the house will become different to that of outside the house. The outside pressure will remain the same, but the pressure inside the house will reduce; becoming less than the outside pressure, this is referred to as 'negative pressure'. When there is negative pressure in the house, air will enter evenly through all the inlets, regardless of where the fans are situated. The greater the negative pressure (the difference in pressure between outside and inside the house), the faster the speed of air coming in through inlet.

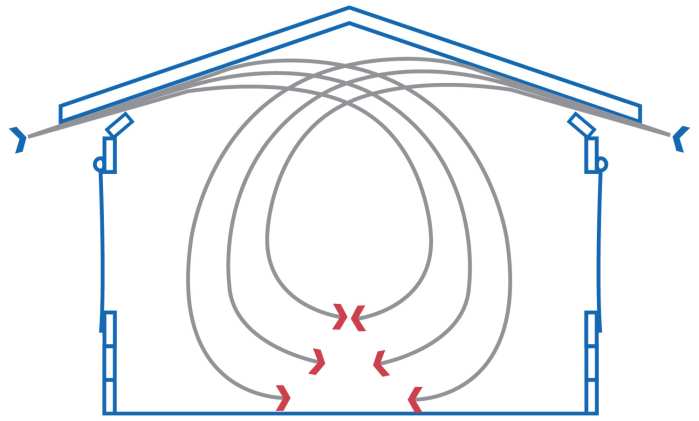

The setting and management of the side inlets is very important. Open inlets should be distributed evenly on both sides of the house as this helps produce a uniform environment. The type of inlet you use must direct the cold incoming air towards the peak of the roof where the warm air congregates. This helps warm the incoming air and in return will reduce the relative humidity of the air, making it easier for the air to absorb moisture which results in a drier house and litter. As a guide, for every 10ᵒC the air is warmed, the relative humidity is halved.

Normally, not all air inlets will need to be opened during minimum ventilation and the inlets that are open must be opened equally to ensure a uniform air flow and distribution.

The recommended minimum inlet opening is approximately 5cm/2in. How many and how wide the inlets are opened will be based on the negative pressure is required, this will depend on:

As a guide for estimating operating pressure, you can assume that an increase of 3-4 Pascal (Pa) will throw the air roughly 1m further into the house. E.g., for a 15-meter-wide house, you can estimate that you’ll need a negative pressure of around 30Pa to ensure the air will arrive to the centre of the roof and give it chance to heat up.

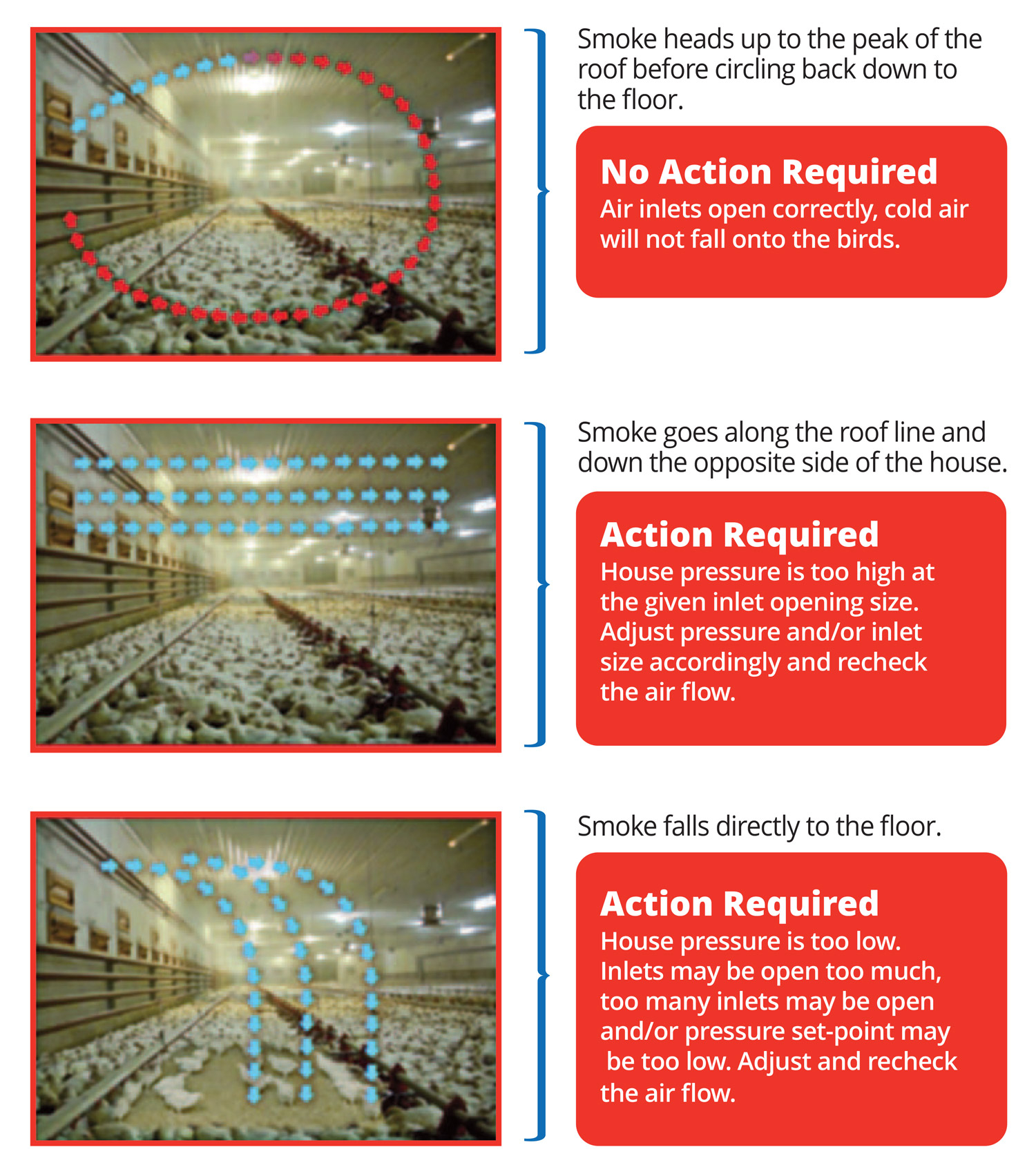

If air inlets are open too much or too many are opened, negative pressure within the house will be reduced (the difference between pressure inside the house and outside will become less) and the speed at which the air enters the house will be too slow so that it falls directly on to the birds. Having fewer inlets that are open the "correct" amount (5 cm/2 minimum) is better than having all the inlets not open enough. Inlet management involves finding the best combination of: the minimum opening size of inlets, the negative pressure in the house, the setting the direction of air.

Inlet air flow and operating pressure should be tested, checked and confirmed using a smoke test. Air should flow to the centre of the house (peak of the roof) before slowing and moving down towards the floor.

Another important area to manage is the minimum ventilation cycle timer. This is where the extraction fans come on for a certain period of time, it is crucial as this air exchange keeps air quality high. During brooding and when the birds are still young, be sure that the minimum ON time is enough for the air to reach the peak of the ceiling, and then start to travel down to the floor to ensure the cold incoming air does not drop directly onto the birds. A cycle time of 500 seconds is widely used and in a 15m wide house, the minimum on time could be between 30 and 45 seconds but this should be checked with a smoke test. Minimum ventilation programs that are based on things like bird bodyweight should be only seen as a guide, its important to use the birds body language and your initial evaluation of the air to decide what changes to make. The following signs would suggest that the minimum ventilation rate should be increased:

The best indicator of how well your ventilation is being managed is the bird’s behaviour and the air quality in the house. It’s important to access the situation of ventilation on a frequent basis and adjust the ventilation regularly to achieve the best environment for your birds to grow in.

Please see Aviagen Turkeys’ “Management Guidelines for Breeding Turkeys – Ventilation Page 76" publication for a more detailed description of ventilation management.